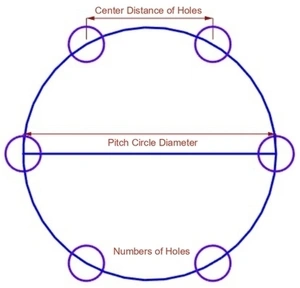

The centre distance between holes is a crucial calculation in machining, fabrication, and mechanical design. It ensures accurate hole placement in components such as flanges, gears, jigs, fixtures, and mounting plates. Proper spacing between holes is essential for assembly alignment, structural integrity, and functionality in various industrial applications. .

Precision in Assembly – Ensures correct alignment of mating parts in mechanical assemblies.

Structural Integrity – Prevents stress concentration and maintains even load distribution.

Standardization – Helps in maintaining uniform spacing in repetitive machining processes.

Ease of Machining – Facilitates accurate drilling, milling, and boring operations.

Applications of Centre Distance Calculation

Flange Hole Layout – Ensures bolt holes are evenly spaced around a circle.

Gear and Sprocket Mounting – Helps in accurate alignment of shaft holes. .

Jigs and Fixtures Design – Maintains proper hole spacing for work-holding devices.

PCB and Circuit Design – Ensures precise placement of component holes.

The calculation of centre distance between holes is essential for achieving precision in machining and assembly processes. By using this application machinists and engineers can ensure accurate hole placement, improving the quality and functionality of mechanical components.

Center Distance Between Holes

Calculation

Pitch Circle Diameter:

Numbers of Hole :

- Submit

- Clear

- Back

- Go to Demo

Center Distance of Holes: